We Are Open 24 Hours a Day, 7 Days a Week, Including Weekends and Public Holidays.

1. Definition

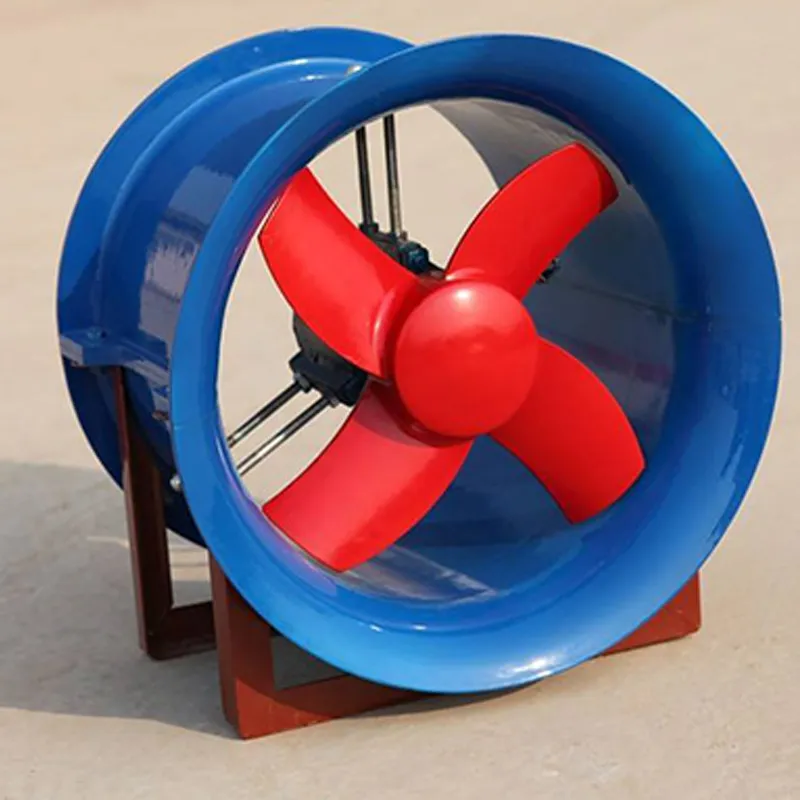

An FRP (Fiber Reinforced Plastic) axial flow fan is a type of ventilation equipment that uses the rotation of a propeller - shaped impeller to make the gas flow in the axial direction along the axis of the fan housing. The fan body is made of fiber - reinforced plastic, which combines the advantages of high - strength fibers and plastics.

2. Working Principle

The motor of the FRP axial flow fan drives the impeller to rotate at high speed. When the impeller rotates, the blades push the air in the axial direction. According to the principle of fluid mechanics, the air is continuously sucked in from the inlet of the fan and then discharged from the outlet at a certain speed and pressure, achieving the purpose of ventilation and air - displacement.

3. Structural Features

- FRP Material: The use of FRP material gives the fan excellent corrosion resistance, which is suitable for harsh environments such as chemical plants, sewage treatment plants, and coastal areas. It can withstand the erosion of various corrosive gases and liquids, greatly extending the service life of the fan.

- Lightweight Design: Compared with traditional metal - made fans, FRP axial flow fans are much lighter in weight. This not only makes installation and maintenance more convenient but also reduces the load on the supporting structure, saving costs in related infrastructure construction.

- Optimal Blade Design: The impeller blades are designed with an aerodynamic shape, which can effectively improve the efficiency of air - delivery. The angle and shape of the blades are optimized to ensure a large air - volume output while reducing energy consumption.

4. Performance Advantages

- High - efficiency Air - delivery: FRP axial flow fans can provide a large air volume under a relatively low - power operation, which is very suitable for large - scale ventilation projects. They can quickly replace the air in a large space, ensuring good air quality.

- Low Noise: Thanks to the reasonable design of the impeller and the use of high - quality materials, these fans operate with relatively low noise, which is especially important for environments where noise control is required, such as offices, hospitals, and residential areas.

- Energy - saving: With advanced manufacturing technology and optimized design, FRP axial flow fans can achieve high - efficiency operation with less energy consumption, helping users save energy costs in the long - term operation.

5. Application Areas

- Industrial Ventilation: Widely used in factories, workshops, and power plants to discharge hot air, dust, and harmful gases, ensuring a healthy working environment for workers.

- Building Ventilation: Applied in commercial buildings, residential buildings, and underground garages to provide fresh air and exhaust stale air, improving the indoor air quality and comfort.

- Agricultural Applications: Used in greenhouses, livestock farms, etc. to control the temperature and humidity in the environment, creating a suitable growth environment for plants and livestock.

In conclusion, the FRP axial flow fan, with its unique material properties, excellent performance, and wide range of applications, has become an important choice for modern ventilation systems.

What Our Customers Say About FRP Axial Flow Fan

Frp Axial Flow Fan FAQ

-

Q: What is an FRP axial flow fan?

A: An FRP axial flow fan is a fan made from fiberglass reinforced plastic, used to circulate air in industrial ventilation systems.

-

Q: What are the key benefits of using FRP axial flow fans?

A: They offer corrosion resistance, lightweight design, and high energy efficiency, making them ideal for harsh industrial environments.

-

Q: Where are FRP axial flow fans used?

A: These fans are commonly used in power plants, chemical plants, and ventilation systems in manufacturing facilities.

-

Q: How do FRP axial flow fans compare to other types of fans?

A: FRP axial flow fans are more durable and require less maintenance compared to traditional metal fans due to their corrosion-resistant properties.

Address

20 Xingyuan South Street, Zaoqiang County, Hengshui City, Hebei Province, China